Servo Motor

A servo motor is an electromechanical device designed to provide precise control of position, speed, and torque, making it essential in advanced applications like robotics, industrial automation, aerospace, and medical devices. Unlike conventional motors, servo motors operate within a closed-loop control system that continuously monitors output through feedback sensors, such as encoders or resolvers, and adjusts input signals to achieve the desired performance. This closed-loop feedback enables servo motors to deliver exceptional precision, responsiveness, and high torque even at low speeds, making them ideal for dynamic environments. They are compact yet powerful, with configurations including brushed and brushless DC motors, as well as AC motors, each tailored to meet specific operational demands.

A complete servo system consists of a motor, a controller to interpret input commands, a driver or amplifier to regulate power delivery, and a feedback sensor to ensure real-time corrections. The combination of these components allows servo motors to achieve unparalleled accuracy and efficiency in applications such as CNC machines, robotic arms, aircraft control surfaces, and advanced surgical tools. Their ability to blend reliability, adaptability, and performance underpins their widespread adoption in industries that require precise and responsive motion control solutions.

United Motion Inc. is the authorized distributor of Oli Motions Control in North America.

Oli’s M series servo motors cover 24-72VDC and 200-240V/380-480VAC supply voltages. Power range from 50W to 30kW, with Motor protection level being IP65/67, and can support several encoders like 2500P/17bit/20bit etc.

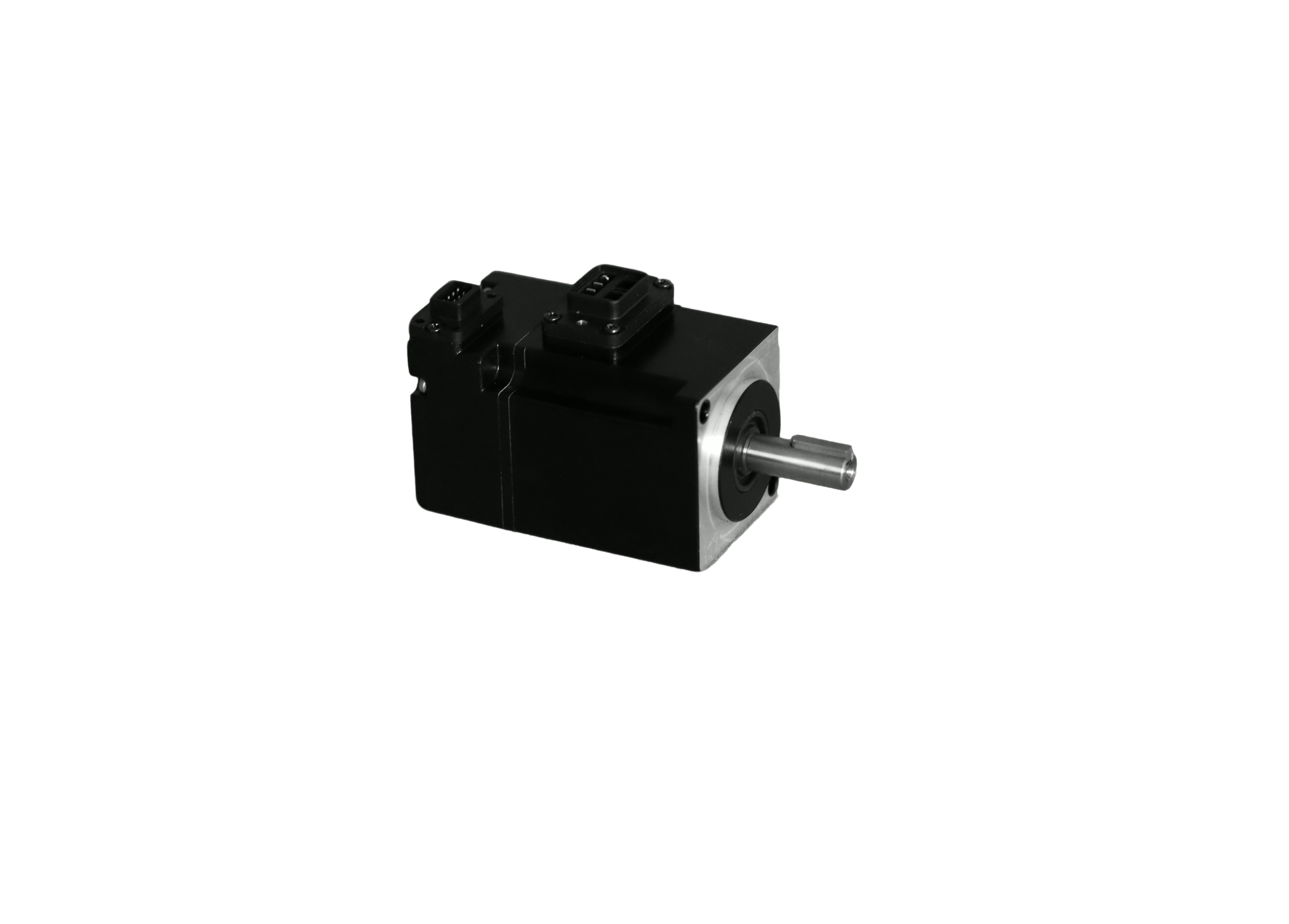

DC Servo Motors

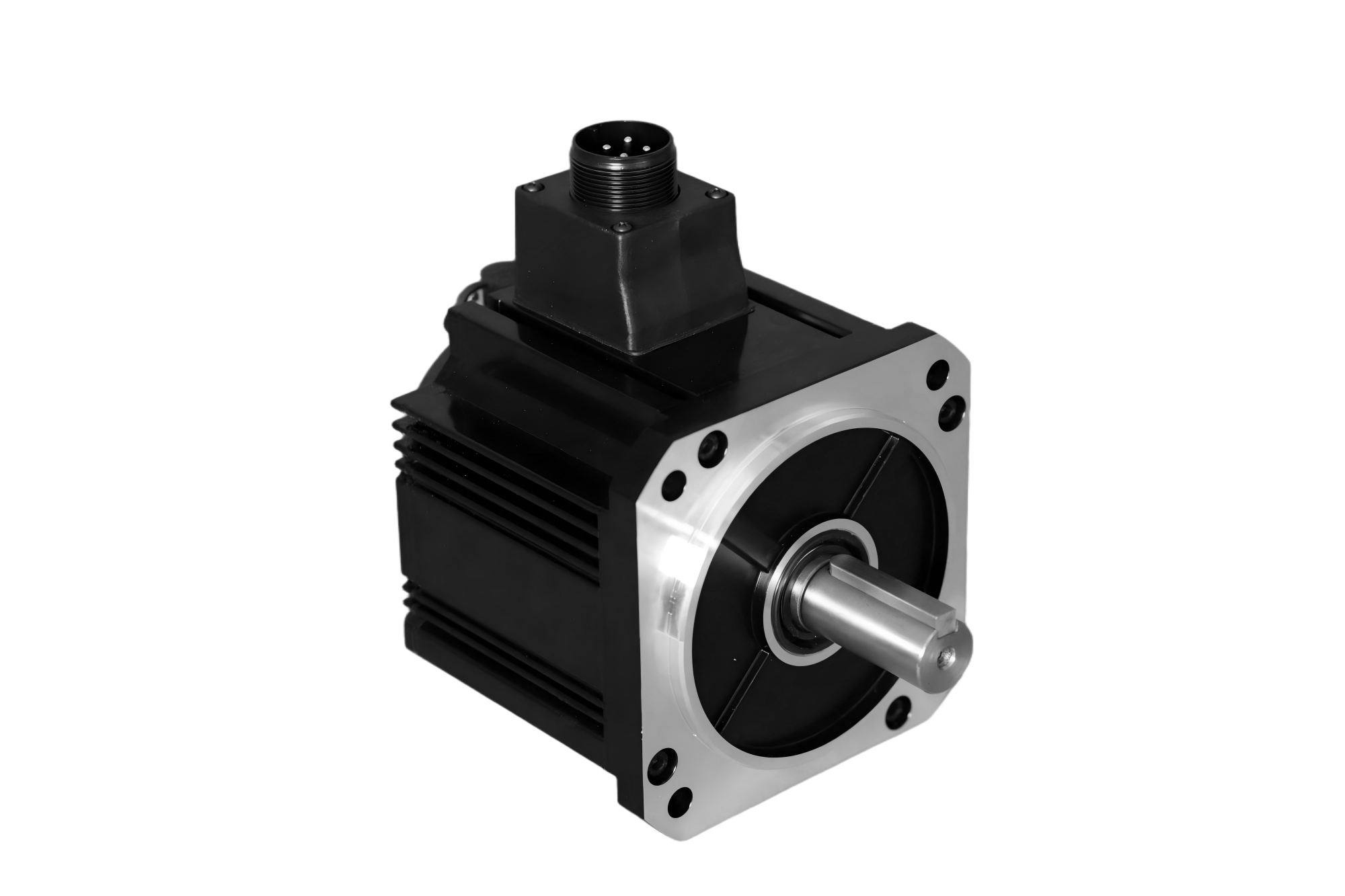

AC Servo Motors

PRIMARY FEATURES

01

Multiple Inertia Options for Different Applications

Low inertia servo motors enable rapid acceleration and deceleration, making them ideal for fast pick-and-place, robotics, and precision assembly tasks.

Medium inertia servo motors balance speed and stability, suited for packaging, textiles, and general automation with moderate load changes.

High inertia servo motors handle heavy loads and inertial mismatches, delivering stable, precise performance in conveyors, presses, and printing systems.

02

Low Cogging Torque (Torque Ripple < 3%)

By optimizing the electromagnetic structure, the motor achieves exceptionally low cogging torque with torque ripple maintained below 3%. This ensures smooth operation at low speeds and high precision, making it perfect for applications requiring exceptional stability, such as CNC machines and high-end printing equipment.

03

High Power Density with Premium Efficiency

The servo motor offers high power density, delivering greater output power in a compact size while maintaining premium efficiency. Advanced materials and optimized electromagnetic design enhance energy efficiency, reducing operating costs and environmental impact. This makes it an excellent choice for energy-conscious industrial applications.

04

3.5 Times Overload Capability

With the ability to provide up to 3.5 times the rated torque for short periods, this motor is well-equipped to handle high-load conditions effortlessly. This robust overload capacity is ideal for applications such as pressing machines, heavy-duty machinery, and dynamic load scenarios, ensuring reliability under demanding conditions.

05

2 Times Overspeed Capability

The motor supports a wide speed range, reaching up to twice the rated speed. Its versatility ensures high efficiency and stability in both high-speed and low-speed operations, making it suitable for applications like textile machines and automated conveyor systems.

06

High Accuracy Encoder

Compatible with high-resolution encoders (20-bit and above), the servo motor delivers exceptional accuracy in position and speed control. This makes it an outstanding choice for applications requiring ultra-precision, such as semiconductor manufacturing and precision measurement instruments, meeting the demands of Industry 4.0 for high-accuracy control.

Customer Service

United Motion Inc.’s motion solution apply in diverse areas all around the world.

Our sales and engineering support teams are ready to assist you with any questions, including quotation, application support, and product configuration.

Please submit your requirements through our Custom Service Form to ensure a faster response. Or you can reach us at info@unitedmotioninc.com for general inquiries.

Tell Us About Your Application Requirements

United Motion Inc welcomes inquiries and challenges. If you find our standard products cannot meet your need, please feel free to contact us for customization. Our professional engineering and service team will quickly review your need and propose a solution if we can make it.

We look forward to communicating and collaborating with you!