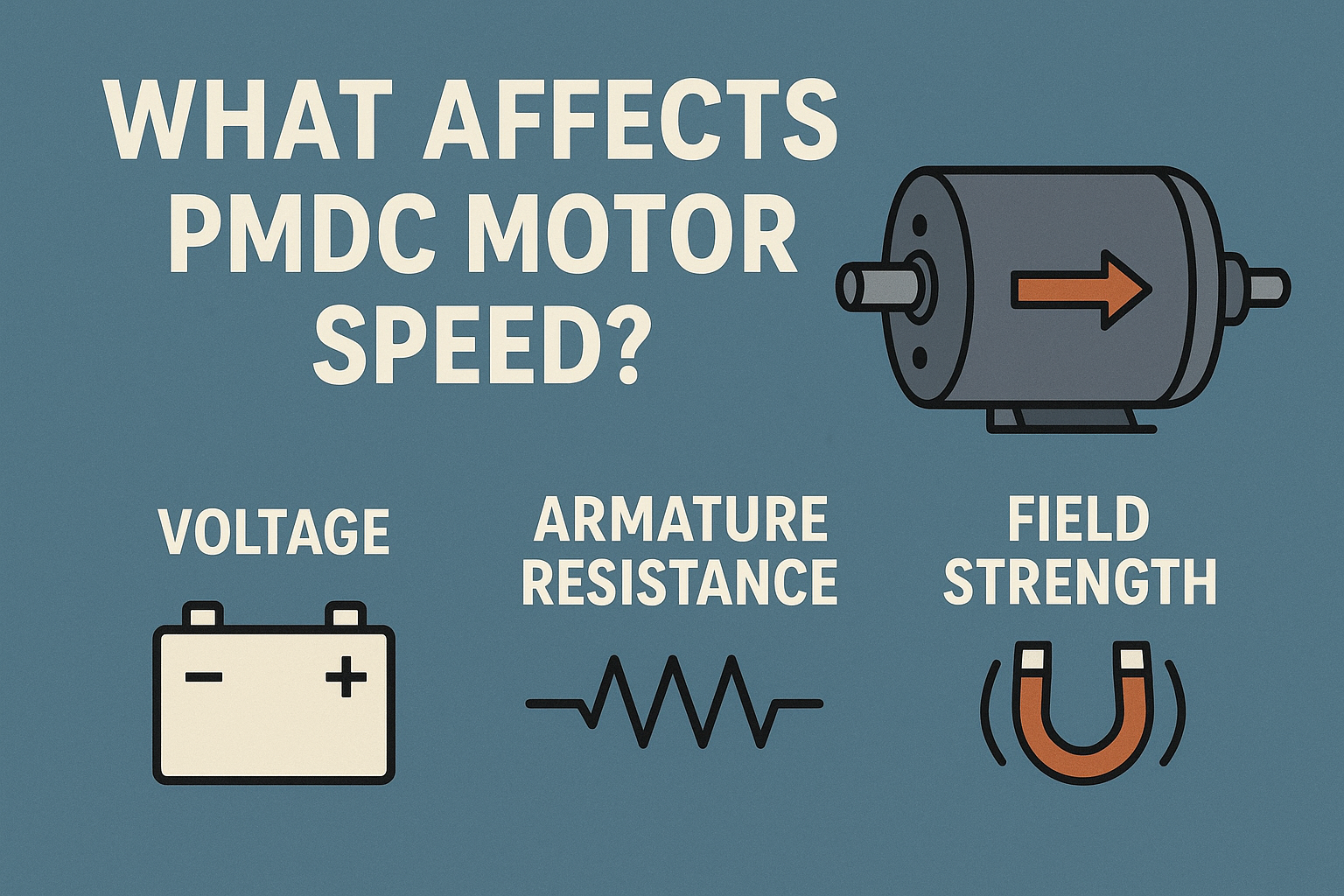

What Affects PMDC Motor Speed?

Permanent Magnet DC (PMDC) motors are widely used across industries because of their simple design, reliable torque characteristics, and ease of control. However, one of the most critical aspects of their performance — and one that often raises questions — is speed. What makes a PMDC motor run faster or slower? Why does speed change under certain conditions, even when the voltage supply seems constant? In this comprehensive article, we’ll explore every factor that influences the speed of PMDC motors. We’ll break down the physical, electrical, and mechanical influences behind these changes. By the end, you’ll understand how to control PMDC motor speed more effectively for your applications — whether you’re working in robotics, automation, medical equipment, or industrial machinery.

Understanding the Basics of PMDC Motor Speed

Before diving into the influencing factors, it’s important to understand what defines the speed of a PMDC motor. The speed of a PMDC motor primarily depends on two parameters: the supply voltage and the magnetic field strength generated by the permanent magnets.

In simple terms, the motor speed can be expressed by the equation:

𝑁=𝑉−IₐRₐ/𝐾𝜙

Where:

N = Speed (RPM)

V = Supply Voltage

Iₐ = Armature Current

Rₐ = Armature Resistance

K = Motor Constant

φ (phi) = Magnetic Flux per Pole

From this equation, we can see that the motor speed is directly proportional to the applied voltage and inversely proportional to the magnetic field flux. Therefore, any factor that alters voltage, current, resistance, or flux will influence speed. But this is just the start. In real-world operation, there are many other interconnected factors that shape the performance of a PMDC motor.

The Role of Supply Voltage

The most straightforward factor that affects PMDC motor speed is the applied voltage. When voltage increases, the armature current also increases, which enhances torque and ultimately raises speed. Conversely, when voltage drops, the motor runs slower. However, there’s a delicate balance. Applying too high a voltage can cause excessive current flow, leading to heat buildup, insulation damage, and reduced motor life. Many users mistakenly think that running a motor slightly above its rated voltage will increase productivity, but this often shortens lifespan significantly. For example, if a 24V PMDC motor is consistently operated at 30V, the short-term speed increase may seem attractive, but the armature windings will overheat, brushes will wear out faster, and magnetic flux may weaken over time due to thermal demagnetization. That’s why voltage regulation is one of the most important practices for maintaining stable PMDC motor performance.

Armature Resistance and Internal Losses

Another key factor that influences PMDC motor speed is armature resistance (Rₐ). Every winding in the armature has some resistance, which causes a voltage drop as current passes through. This internal voltage drop (IₐRₐ) directly reduces the effective voltage across the armature, leading to a lower speed. Over time, armature resistance can change slightly due to temperature rise or aging. As resistance increases, the voltage drop becomes more significant, which means the motor runs slower even under the same supply voltage. It’s worth noting that manufacturers like United Motion Inc. design PMDC motors with optimized winding configurations to minimize internal losses. This ensures better speed regulation and higher energy efficiency under load conditions.

Magnetic Flux Strength

The magnetic flux (φ) in a PMDC motor is created by permanent magnets, which replace the field windings found in conventional DC motors. This flux plays a critical role in determining speed because it affects the counter-electromotive force (back EMF). If magnetic flux decreases — due to aging magnets, high operating temperatures, or demagnetization — the back EMF drops. As a result, the motor draws more current and runs faster, often uncontrollably. This might seem beneficial at first glance, but it can lead to instability, noise, and higher wear. Similarly, stronger magnetic flux increases back EMF, which limits the armature current and reduces speed. Therefore, any environmental or mechanical factor that impacts the magnet’s strength will also affect motor speed consistency.

Load Torque and Mechanical Resistance

The load connected to a PMDC motor has a direct impact on its speed. As load torque increases, the motor must generate more torque to overcome it, which means drawing more armature current. This increased current produces a higher voltage drop across the armature resistance (IₐRₐ), reducing the net voltage available for speed. In other words, as load increases, speed decreases — a characteristic common to most DC motors.

Below is a simplified chart illustrating this relationship:

| Load Torque (N·m) | Speed (RPM) | Armature Current (A) |

|---|---|---|

| 0.0 | 3600 | 0.5 |

| 0.2 | 3400 | 1.1 |

| 0.4 | 3200 | 1.8 |

| 0.6 | 2900 | 2.4 |

| 0.8 | 2500 | 3.1 |

| 1.0 | 2100 | 3.8 |

This chart clearly shows that as the load increases, the motor speed decreases, while the armature current rises. The steeper the drop, the lower the speed regulation capability of the motor.

Temperature Effects

Temperature plays an often-overlooked role in PMDC motor performance. When the motor operates continuously under load, winding temperatures rise. This temperature increase leads to a rise in armature resistance, causing additional voltage drop and lowering speed. In extreme conditions, high temperatures may also weaken permanent magnets, reducing magnetic flux and altering speed behavior permanently. To counter this, high-quality PMDC motors — such as those designed by United Motion Inc. — incorporate materials with superior thermal stability. The motor housings are engineered for efficient heat dissipation, and advanced insulation materials are used to maintain consistent performance under varying thermal conditions.

Brush and Commutator Condition

Since PMDC motors rely on a mechanical commutator and brushes for current transfer, their condition directly influences speed stability. When brushes wear out, lose contact, or accumulate carbon deposits, electrical resistance at the contact interface increases. This resistance can cause voltage fluctuations, sparking, and intermittent current supply to the armature, all of which result in speed variation. Routine maintenance and timely brush replacement are therefore essential for stable motor speed performance. Poor brush condition not only affects speed but also leads to torque ripple and higher noise levels.

Power Supply Stability

Even if the motor is designed perfectly, its speed will fluctuate if the power supply is unstable. Sudden voltage dips or surges directly translate to speed variation. For instance, in battery-powered systems, the voltage can drop as the battery discharges, causing the motor to slow down. In industrial applications, PMDC motors are often paired with regulated DC power supplies or pulse-width modulation (PWM) controllers to ensure smooth and precise speed control. PWM allows speed adjustment without reducing torque significantly, which makes it ideal for applications like conveyors, actuators, and automated tools.

Friction and Bearing Quality

Mechanical friction is another subtle but powerful factor that affects speed. Bearings, shaft alignment, and lubrication all influence the ease with which the rotor spins. When bearings are dry, worn, or misaligned, the frictional torque increases, forcing the motor to work harder to maintain speed. Over time, this not only reduces efficiency but also accelerates wear on other components. That’s why United Motion Inc. places strong emphasis on precision bearing design and lubrication optimization, ensuring low mechanical losses and consistent speed over long operating hours.

Environmental Factors

External conditions — such as humidity, dust, and temperature — can have a cumulative effect on motor performance. In humid environments, moisture can lead to corrosion in the commutator or magnet surfaces, affecting flux strength. Dust particles can enter the housing and increase mechanical resistance. For applications in harsh or outdoor environments, motors with sealed enclosures (IP-rated housings) are strongly recommended. This not only preserves speed stability but also extends service life.

Aging and Wear

Every motor, regardless of quality, undergoes aging. Over time, magnet strength may decrease slightly, brushes wear down, and bearings lose their original smoothness. These changes collectively lead to subtle speed reductions and efficiency loss. Preventive maintenance and timely replacement of consumable parts can dramatically extend the life and speed consistency of PMDC motors.

The Impact of Speed Control Techniques

Modern PMDC motor applications often rely on electronic speed controllers, which modulate the applied voltage or duty cycle to achieve precise speed control. The most common methods include:

- Variable Voltage Control: Adjusting supply voltage to control speed linearly.

- PWM (Pulse Width Modulation): Maintaining constant voltage while controlling the average current via duty cycle.

- Armature Resistance Control: Inserting external resistance to reduce voltage drop (rarely used today due to inefficiency).

PWM control is now the preferred method, as it provides excellent efficiency and torque retention.

Comparative Example: Controlled vs. Uncontrolled PMDC Motor

Let’s compare two identical PMDC motors — one using a basic voltage source and the other controlled via a PWM driver.

| Condition | Uncontrolled Motor | PWM-Controlled Motor |

|---|---|---|

| Voltage Variation | ±10% fluctuation | Stable (regulated) |

| Load Speed Drop | 25% under full load | 10% under full load |

| Efficiency | 70% | 85% |

| Heat Generation | High | Low |

| Longevity | Moderate | High |

This comparison highlights why electronic speed control is essential for consistent, long-term motor performance.

Real-World Industrial Implications

In industries like robotics, medical devices, and factory automation, speed stability is critical. A small variation in motor speed can lead to positional errors, uneven product quality, or timing mismatches in synchronized systems. That’s why companies such as United Motion Inc. not only manufacture high-quality PMDC motors but also provide engineering guidance for selecting suitable controllers, bearings, and operating environments. Proper integration ensures that the end application maintains precise performance over years of operation.

Preventive Practices for Maintaining Speed Stability

To ensure consistent PMDC motor speed over time, engineers and technicians should follow these best practices:

- Maintain Proper Voltage Supply: Always use regulated power sources or quality controllers.

- Monitor Temperature: Keep the motor within its rated temperature range.

- Inspect Brushes Regularly: Replace them before excessive wear occurs.

- Lubricate Bearings: Use appropriate lubricants periodically.

- Clean the Motor: Keep dust and moisture away from moving parts.

- Avoid Overloads: Operate within the rated torque to prevent speed drops.

- Use PWM Controllers: Achieve precise control without efficiency loss.

By following these simple practices, users can ensure the motor delivers stable speed and long operational life.

References

Chapman, S. J. Electric Machinery Fundamentals. McGraw-Hill Education.

Hughes, A. & Drury, B. Electric Motors and Drives: Fundamentals, Types and Applications. Elsevier.

Fitzgerald, A. E., Kingsley, C., & Umans, S. D. Electric Machinery. McGraw-Hill.

IEEE Transactions on Energy Conversion, Vol. 37, 2023.