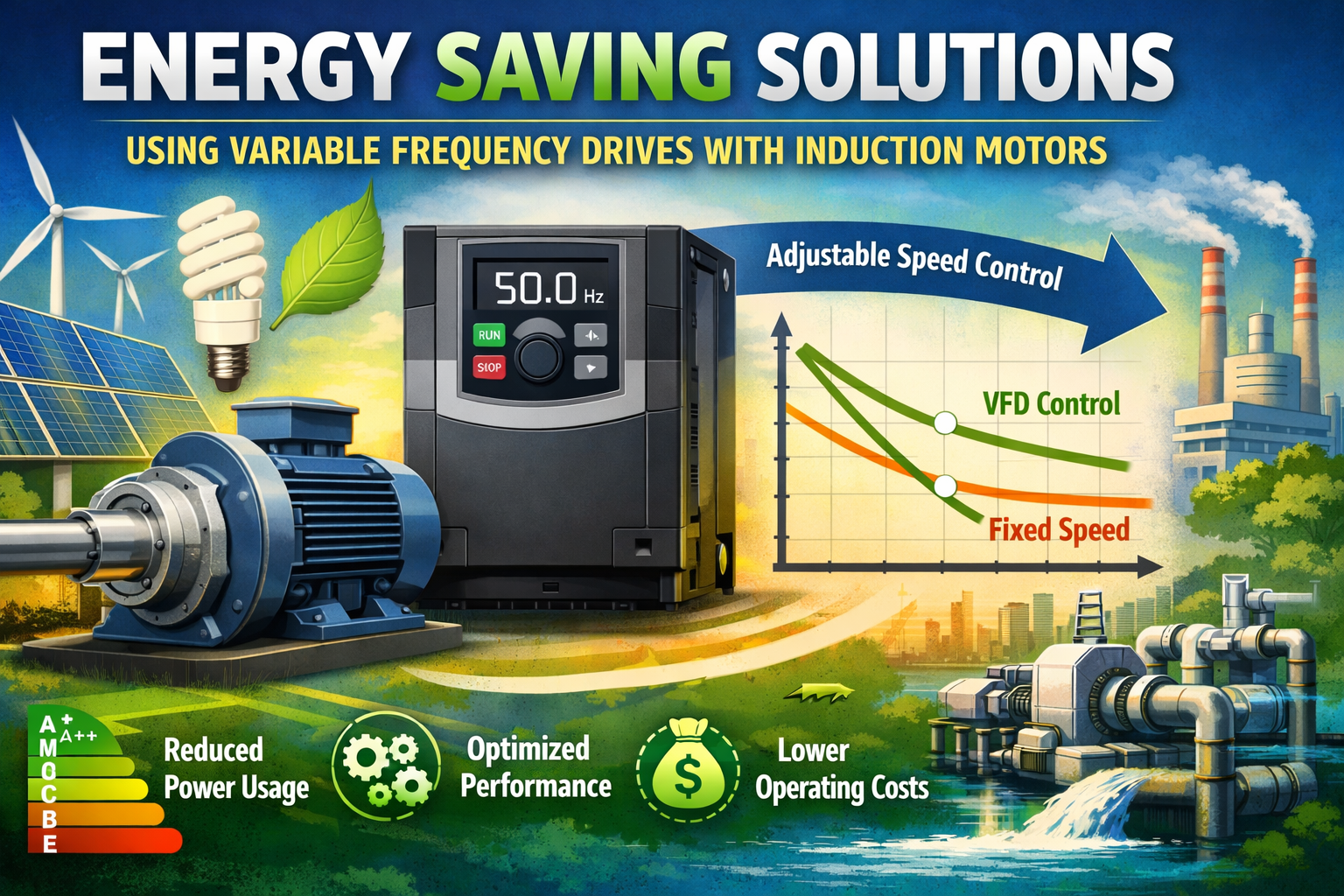

Energy Saving Solutions Using Variable Frequency Drives with Induction Motors

Energy costs continue to rise, and efficiency targets are becoming stricter across manufacturing, building services, water treatment, and automation industries. For many operations, electric motors are the largest single source of electricity consumption. Among them, induction motors dominate due to their durability, simple structure, and cost-effectiveness. However, traditional induction motor systems often run at constant speed, even when full output is not required. This mismatch between load demand and motor speed leads to wasted energy, higher operating costs, and unnecessary wear on equipment.

Variable Frequency Drives (VFDs) provide a practical and proven solution to this problem. By adjusting the frequency and voltage supplied to an induction motor, a VFD allows precise speed and torque control based on real operating needs. This article explains how energy saving solutions using variable frequency drives with induction motors work in real-world applications.

Understanding Induction Motors and Their Energy Challenges

Induction motors are widely used because they are robust, easy to maintain, and suitable for continuous operation. They are commonly found in pumps, fans, compressors, conveyors, mixers, and machine tools. In many legacy systems, these motors operate directly from the power grid at a fixed frequency, typically 50 Hz or 60 Hz. This means the motor runs at nearly constant speed regardless of actual process demand.

The main energy challenge with fixed-speed induction motors is inefficiency at partial load. For example, a centrifugal pump or fan often requires only 60–70% of its rated flow for most of the day. Without speed control, flow is reduced using throttling valves or dampers. While this method controls output, the motor still consumes close to full power. As a result, energy is wasted as heat, pressure loss, and mechanical stress.

Another challenge is high inrush current during motor startup. Direct-on-line starting can draw six to eight times the rated current, causing voltage dips, increased demand charges, and mechanical shock to couplings and bearings. Over time, this reduces motor life and increases maintenance costs.

What Is a Variable Frequency Drive and How It Works?

A variable frequency drive, also known as a VFD or inverter, is an electronic device that controls motor speed by adjusting the frequency and voltage of the power supply. The basic structure of a VFD includes a rectifier, a DC bus, and an inverter stage. The rectifier converts incoming AC power to DC, the DC bus smooths and stores energy, and the inverter generates a variable-frequency AC output to drive the motor.

By changing the output frequency, the VFD directly controls the motor’s synchronous speed. At the same time, voltage is adjusted to maintain proper magnetic flux in the motor. This coordinated control ensures efficient torque production across a wide speed range. Modern VFDs use advanced control algorithms, such as V/f control, sensorless vector control, and closed-loop vector control, to optimize performance and efficiency. From an energy-saving perspective, the most important advantage of a VFD is its ability to match motor speed to actual load demand. Instead of running at full speed all the time, the motor only uses the energy required for the task at hand.

The Physics Behind Energy Savings

The energy-saving potential of variable frequency drives becomes especially clear when applied to variable torque loads such as pumps and fans. According to the affinity laws, flow is proportional to speed, pressure is proportional to the square of speed, and power is proportional to the cube of speed. This means that even a small reduction in motor speed can lead to a significant reduction in power consumption.

For example, reducing motor speed by 20% can lower power consumption by nearly 50% in centrifugal applications. This is why VFDs are considered one of the most effective energy-saving technologies in industrial and commercial systems. Instead of wasting energy through mechanical restrictions, the motor itself operates more efficiently at lower speeds. In constant torque applications such as conveyors and extruders, energy savings are still possible. Although the power reduction is not as dramatic as in variable torque loads, VFDs improve efficiency by eliminating unnecessary full-speed operation and reducing losses during acceleration and deceleration.

Common Applications of VFDs with Induction Motors

One of the most common applications of variable frequency drives is in pump systems. Water supply, wastewater treatment, chemical processing, and HVAC systems all rely heavily on pumps. In these environments, demand often changes throughout the day. A VFD-controlled induction motor adjusts pump speed automatically, maintaining stable pressure or flow while minimizing energy use.

Fans and blowers represent another major application. In ventilation and air handling systems, airflow requirements vary based on occupancy, temperature, and process conditions. Using dampers to control airflow wastes energy, while VFDs allow direct speed control. This results in quieter operation, lower electricity bills, and longer equipment life.

Conveyor systems in manufacturing and logistics also benefit from VFDs. Speed control improves process flexibility and reduces mechanical stress during startup. Soft starting and stopping minimize product damage and extend the life of belts, gearboxes, and bearings.

Compressors, mixers, and machine tools further demonstrate the versatility of energy saving solutions using variable frequency drives with induction motors. In each case, matching motor output to real demand leads to measurable efficiency gains.

Energy Savings in HVAC Systems

HVAC systems are among the largest consumers of electrical energy in commercial buildings. Chillers, air handling units, cooling towers, and circulation pumps often operate for long hours. Traditionally, these systems were designed for peak load conditions, even though peak demand occurs only a small portion of the time.

By integrating VFDs with induction motors, HVAC systems become far more responsive and efficient. For example, a VFD-controlled supply fan can adjust speed based on indoor air quality or temperature feedback. Instead of cycling on and off, the motor runs continuously at the optimal speed, reducing energy waste and improving comfort. In chilled water systems, VFDs on pumps and cooling tower fans help maintain stable temperatures while significantly lowering power consumption. Many building owners report energy savings of 30% or more after retrofitting VFDs into existing HVAC installations.

Industrial Energy Efficiency and Cost Reduction

In industrial environments, energy efficiency is directly linked to operating costs and competitiveness. Electricity expenses can represent a large portion of total production costs, especially in energy-intensive industries such as metals, chemicals, food processing, and packaging.

Variable frequency drives help industrial users reduce energy consumption while improving process control. For example, in a food processing plant, conveyors and mixers often operate at different speeds depending on product type. A VFD allows operators to adjust motor speed precisely, avoiding unnecessary energy use and improving product consistency.

Another important benefit is reduced maintenance. Soft starting eliminates mechanical shock, which reduces wear on shafts, couplings, and bearings. Lower operating temperatures also extend motor insulation life. Over time, these factors contribute to lower total cost of ownership.

Power Quality and Grid Benefits

Beyond direct energy savings, VFDs can also improve overall power quality when properly selected and installed. Controlled acceleration reduces peak current demand, which can lower utility demand charges. In facilities with multiple large motors, this can lead to significant cost savings.

Modern VFDs are designed with built-in filters and advanced control techniques to reduce harmonic distortion. When combined with proper system design, they help maintain stable voltage levels and protect sensitive equipment. This is especially important in plants that use automation systems, PLCs, and precision electronics.

Selecting the Right Induction Motor for VFD Applications

Not all induction motors are equally suited for variable frequency drive operation. When selecting a motor for use with a VFD, several factors should be considered, including insulation class, cooling method, and bearing protection.

VFD operation can introduce voltage spikes and higher switching frequencies, which place additional stress on motor insulation. Motors designed for inverter duty typically feature reinforced insulation systems to handle these conditions. Proper cooling is also important, especially at low speeds where the motor’s built-in fan is less effective.

At United Motion Inc., motor solutions are designed with VFD compatibility in mind. By matching the right induction motor with the appropriate drive, customers can achieve reliable operation and maximum energy efficiency.

Control Strategies and Smart Energy Management

Advanced control strategies further enhance the energy-saving potential of VFD systems. Sensorless vector control provides accurate speed and torque control without the need for external encoders. Closed-loop control offers even higher precision for demanding applications.

When integrated with automation systems, VFDs become part of a broader energy management strategy. Data from sensors and controllers allows real-time optimization of motor performance. Predictive maintenance, remote monitoring, and adaptive control all contribute to long-term efficiency gains.

As Industry 4.0 continues to evolve, smart VFDs and connected induction motors will play a key role in reducing energy consumption and improving system transparency.

Retrofitting Existing Systems with VFDs

One of the most attractive aspects of variable frequency drives is their suitability for retrofit projects. Many facilities operate aging equipment that still functions well mechanically but wastes energy due to outdated control methods.

Retrofitting a VFD onto an existing induction motor often delivers a fast return on investment. In many cases, payback periods are measured in months rather than years. The process typically involves evaluating the load profile, selecting a compatible drive, and making minor electrical and control system upgrades.

Environmental Impact and Sustainability

Energy efficiency is not only about cost savings. Reducing electricity consumption also lowers greenhouse gas emissions and supports sustainability goals. As governments and organizations adopt stricter environmental regulations, energy-efficient motor systems become a strategic advantage.

Variable frequency drives help companies meet carbon reduction targets without sacrificing performance. By optimizing motor operation, facilities can reduce their environmental footprint while maintaining productivity and reliability.

Real-World Results and Case Examples

In real-world applications, energy saving solutions using variable frequency drives with induction motors consistently deliver measurable results. Pump systems often achieve energy savings of 20–50%. HVAC installations frequently report reduced noise, improved comfort, and lower maintenance costs. Industrial users benefit from improved process control and reduced downtime.

These outcomes highlight why VFDs are now considered a standard component of modern motor systems rather than an optional upgrade.

Challenges and Best Practices

While the benefits of VFDs are clear, proper implementation is essential. Incorrect sizing, poor parameter settings, or inadequate cooling can reduce efficiency or cause reliability issues. Cable length, grounding, and electromagnetic compatibility must also be considered during installation.

Working with experienced suppliers and engineers helps avoid these challenges. A well-designed system maximizes energy savings while ensuring long-term stability and safety.

The Role of United Motion Inc.

Future Trends in VFD and Motor Technology

The future of energy-efficient motor systems points toward greater integration, intelligence, and automation. Advances in power electronics, digital control, and materials science continue to improve VFD efficiency and reliability.

Permanent magnet motors and hybrid systems are gaining attention, but induction motors paired with VFDs remain a practical and cost-effective solution for many applications. As technology evolves, these systems will become even more efficient and easier to deploy.

References

1. IEC 60034-30-1: Efficiency classes of line operated AC motors

2. U.S. Department of Energy, Improving Motor and Drive System Performance

3. IEEE Industry Applications Society, Adjustable Speed Drive Systems

4. European Commission, Energy Efficient Motor Systems

5. Technical guides and application notes from motor and drive manufacturers

Related blog: What Is an Induction Motor? A Beginner’s Guide