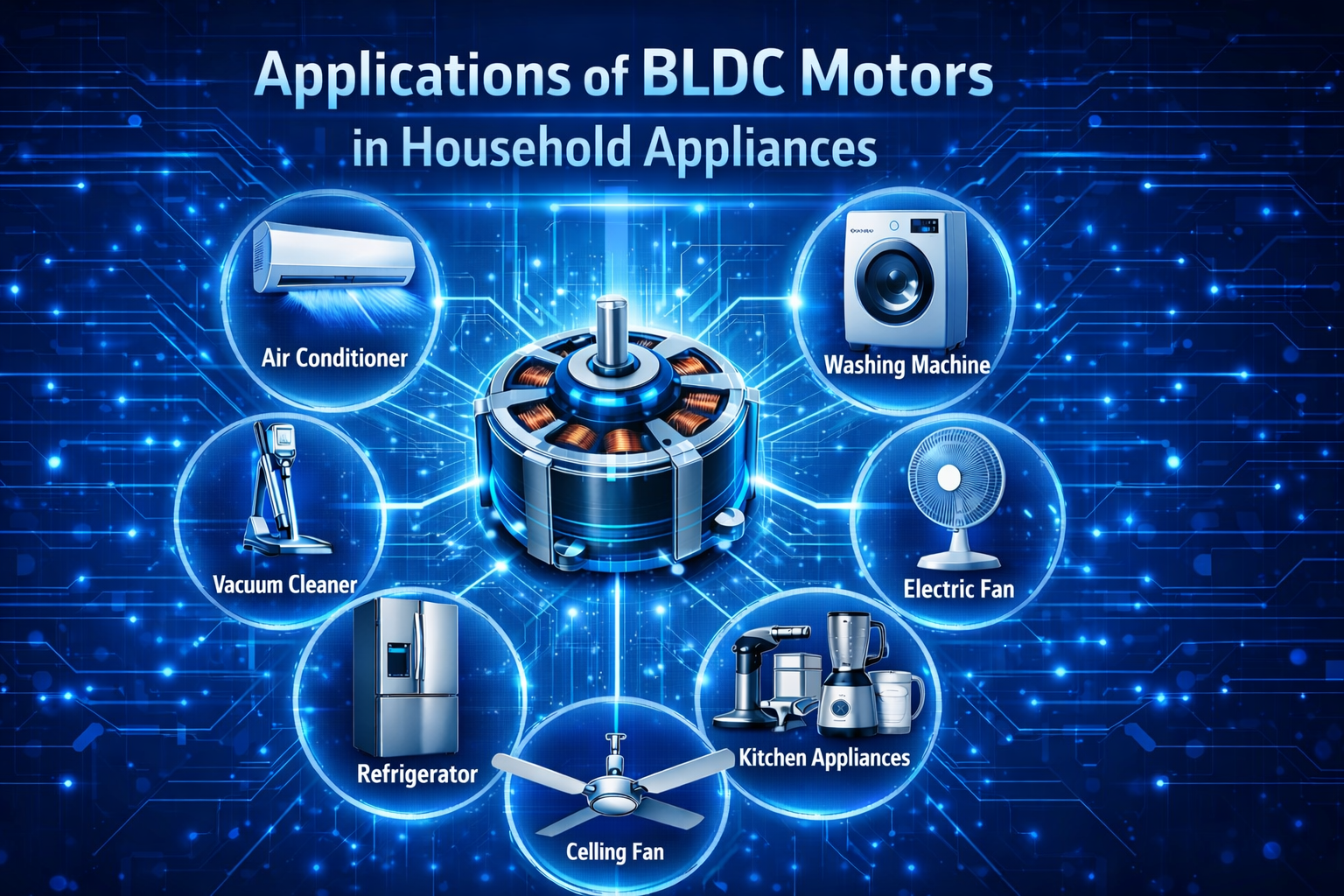

Applications of BLDC Motors in Household Appliances

Brushless DC (BLDC) motors are quietly reshaping the household appliance industry. As energy efficiency standards rise, consumers demand quieter products, and manufacturers compete on performance and reliability, BLDC motor technology has become a key differentiator. From washing machines and refrigerators to vacuum cleaners and air conditioners, BLDC motors now power many of the appliances used daily in modern homes.

For appliance manufacturers, product designers, and sourcing managers, understanding how BLDC motors work—and where they add the most value—is no longer optional. This article explores the real-world applications of BLDC motors in household appliances, explains why buyers are actively searching for BLDC-based solutions, and provides practical insights into selection, benefits, and future trends.

Why BLDC Motors Matter in Modern Household Appliances?

Household appliances are expected to do more while consuming less. Governments enforce stricter energy regulations, consumers compare electricity ratings before purchase, and brands face growing pressure to improve product lifespan and user experience. Traditional brushed motors struggle to meet these expectations due to friction losses, mechanical wear, and lower efficiency.

BLDC motors solve many of these challenges by replacing mechanical brushes with electronic commutation. This design reduces energy loss, heat generation, and maintenance needs. As a result, BLDC motors deliver higher efficiency, longer service life, and more precise speed control—qualities that directly align with appliance industry requirements.

From a buyer’s perspective, BLDC motors are not just a technical upgrade. They are a way to reduce total cost of ownership, comply with global standards, and differentiate products in a competitive market.

What Makes BLDC Motors Different from Traditional Motors?

A BLDC motor operates using a permanent magnet rotor and electronically controlled stator windings. Instead of brushes making physical contact, a controller manages current switching based on rotor position. This fundamental difference brings several practical advantages.

First, the absence of brushes eliminates mechanical wear, which is a common failure point in conventional motors. Second, electronic control allows precise speed and torque regulation, enabling appliances to adapt dynamically to load conditions. Third, efficiency levels are significantly higher, especially under variable-speed operation, which is common in modern appliances.

These characteristics explain why BLDC motors are increasingly preferred in household appliances that require quiet operation, energy savings, and long-term reliability.

Key Advantages of BLDC Motors for Appliance Manufacturers

For appliance manufacturers, BLDC motors offer both engineering and commercial benefits. Higher efficiency translates into better energy labels, which directly influence purchasing decisions. Lower noise improves user satisfaction, particularly in appliances used daily or at night. Longer lifespan reduces warranty claims and after-sales costs.

BLDC motors also support smart control features. With integrated drivers and sensors, they can easily connect to control boards, inverters, and IoT systems. This makes them ideal for smart home appliances, where precise motor control and data feedback are essential.

From a sourcing standpoint, BLDC motors provide scalability and customization. Manufacturers like United Motion Inc. offer tailored voltage ranges, torque profiles, shaft designs, and integrated solutions to match specific appliance requirements.

Applications of BLDC Motors in Washing Machines

Washing machines are one of the most common and impactful applications of BLDC motors in household appliances. Traditional belt-driven systems with brushed motors are being replaced by direct-drive or inverter-driven BLDC motors.

BLDC motors enable variable drum speeds, smooth acceleration, and accurate torque control. This improves washing performance while reducing fabric damage. During spin cycles, the motor can operate at high speeds efficiently, extracting more water and reducing drying time.

Noise reduction is another critical benefit. BLDC motors operate with minimal vibration, making washing machines quieter and more suitable for apartments and shared living spaces. Energy savings achieved through BLDC technology also help manufacturers meet international efficiency standards.

BLDC Motors in Refrigerators and Freezers

Refrigerators operate continuously, making motor efficiency and reliability extremely important. BLDC motors are widely used in compressor drives and fan systems inside modern refrigerators.

In inverter compressors, BLDC motors allow variable-speed operation, adjusting cooling capacity based on load conditions. This prevents frequent start-stop cycles, reduces power consumption, and extends compressor life. Temperature control becomes more stable, which helps preserve food quality.

BLDC fan motors are also used in evaporator and condenser fans. These motors ensure consistent airflow with lower noise and energy use. For manufacturers, this means better product performance and compliance with strict energy regulations.

Applications in Air Conditioners and HVAC Appliances

Air conditioners are among the highest energy-consuming household appliances. The shift from fixed-speed motors to BLDC motors has transformed this category.

BLDC motors are used in indoor blower fans, outdoor condenser fans, and inverter-driven compressors. Their ability to operate at variable speeds allows air conditioners to maintain stable room temperatures while consuming less electricity. This results in higher seasonal energy efficiency ratios and lower operating costs.

Noise reduction is particularly important in air conditioning systems. BLDC motors produce less acoustic noise, improving comfort in residential environments. Their high efficiency also reduces heat generation, improving overall system reliability.

BLDC Motors in Vacuum Cleaners

Vacuum cleaners demand high-speed operation, compact size, and strong suction power. BLDC motors meet these requirements better than traditional universal motors.

Modern cordless vacuum cleaners rely heavily on BLDC motors due to their high power density and efficiency. These motors enable strong suction while extending battery runtime, which is a key selling point for consumers.

BLDC motors also support advanced airflow control and multiple power modes. This allows manufacturers to design lightweight, portable, and high-performance vacuum cleaners that meet evolving consumer expectations.

Use of BLDC Motors in Fans and Air Circulators

Ceiling fans, pedestal fans, and air circulators are another major application area for BLDC motors. Energy efficiency and noise reduction are the primary drivers here.

BLDC fan motors consume significantly less electricity compared to AC induction motors. In many cases, energy savings can exceed 50 percent. This makes BLDC fans attractive in regions with high electricity costs or energy-saving incentives.

Additionally, BLDC motors provide smoother speed control and quieter operation. Users can enjoy consistent airflow without the humming noise often associated with traditional fans.

Kitchen Appliances Powered by BLDC Motors

BLDC motors are increasingly used in kitchen appliances such as mixers, blenders, food processors, and range hoods. These applications benefit from precise speed control and high torque at low speeds.

In mixers and processors, BLDC motors maintain stable speeds even under heavy loads. This improves performance and consistency in food preparation. In range hoods, BLDC motors drive ventilation fans quietly and efficiently, improving indoor air quality.

Durability is another advantage. Kitchen appliances often operate in demanding environments with heat, moisture, and grease. BLDC motors handle these conditions better due to reduced mechanical wear.

BLDC Motors in Dishwashers and Dryers

Dishwashers and dryers rely on motors for water circulation, pumping, and drum rotation. BLDC motors enhance efficiency and reliability in these applications.

In dishwashers, BLDC motors drive circulation pumps and spray arms with precise flow control. This improves cleaning performance while reducing water and energy consumption. In dryers, BLDC motors enable variable drum speeds and efficient airflow management.

The result is improved cleaning and drying performance, lower operating costs, and longer appliance lifespan.

Energy Efficiency and Regulatory Compliance

One of the strongest drivers for BLDC motor adoption is energy regulation. Governments worldwide continue to tighten efficiency standards for household appliances. Products that fail to meet these standards face restricted market access or higher compliance costs.

BLDC motors help manufacturers meet and exceed these requirements. Their high efficiency supports better energy ratings, which directly influence buyer decisions. For export-oriented manufacturers, BLDC motors simplify compliance with international standards such as IEC, DOE, and regional energy labeling programs.

Noise Reduction and User Comfort

Noise is a major factor in household appliance design. Consumers expect appliances to operate quietly, especially in urban living environments.

BLDC motors produce less mechanical and electrical noise due to their brushless design and smoother commutation. This makes them ideal for appliances used frequently or during quiet hours, such as washing machines, refrigerators, and air conditioners.

Lower vibration also reduces structural stress on appliances, improving long-term reliability.

Smart Appliances and Digital Control

The rise of smart home appliances has further increased demand for BLDC motors. These motors integrate easily with electronic controllers, sensors, and communication modules.

BLDC motors support features such as adaptive speed control, predictive maintenance, and remote operation. Appliance manufacturers can use motor data to optimize performance, detect faults early, and enhance user experience.

This integration aligns with the growing trend toward connected and intelligent household appliances.

Customization and Design Flexibility

Household appliances vary widely in size, power requirements, and operating conditions. BLDC motors offer flexibility in design and customization.

Manufacturers like United Motion Inc. provide BLDC motors with different voltage ranges, power ratings, mounting options, and integrated drivers. This allows appliance designers to optimize motor selection for each application rather than relying on one-size-fits-all solutions.

Customization improves performance, reduces system complexity, and shortens development cycles.

Reliability and Total Cost of Ownership

While BLDC motors may have a higher initial cost compared to traditional motors, their long-term benefits often outweigh this difference. Reduced maintenance, lower energy consumption, and longer service life result in a lower total cost of ownership.

For appliance brands, this means fewer warranty claims and stronger brand reputation. For end users, it means reliable appliances that consume less electricity over time.

Future Trends in BLDC Motors for Household Appliances

The use of BLDC motors in household appliances will continue to grow. Advances in motor control electronics, materials, and manufacturing processes are making BLDC solutions more accessible and cost-effective.

Future developments include higher integration levels, sensorless control improvements, and enhanced compatibility with renewable energy systems. As sustainability becomes a core design requirement, BLDC motors will play an even greater role in appliance innovation.

Why Choose United Motion Inc. for BLDC Motor Solutions?

As a professional motor manufacturer, United Motion Inc. focuses on delivering reliable, efficient, and application-specific BLDC motor solutions for household appliances. With experience across multiple appliance categories, United Motion Inc. supports customers from concept development to mass production.

Our BLDC motors are designed to meet global standards and can be customized to match performance, size, and control requirements. Whether for washing machines, HVAC systems, or smart home appliances, United Motion Inc. provides dependable motor solutions that support long-term success.

References

International Electrotechnical Commission (IEC) – Electric Motor Efficiency Standards

U.S. Department of Energy – Appliance Energy Efficiency Regulations

IEEE Industry Applications Society – Brushless DC Motor Technology

European Commission – Ecodesign Requirements for Household Appliances

Academic Journals on Motor Drives and Control Systems