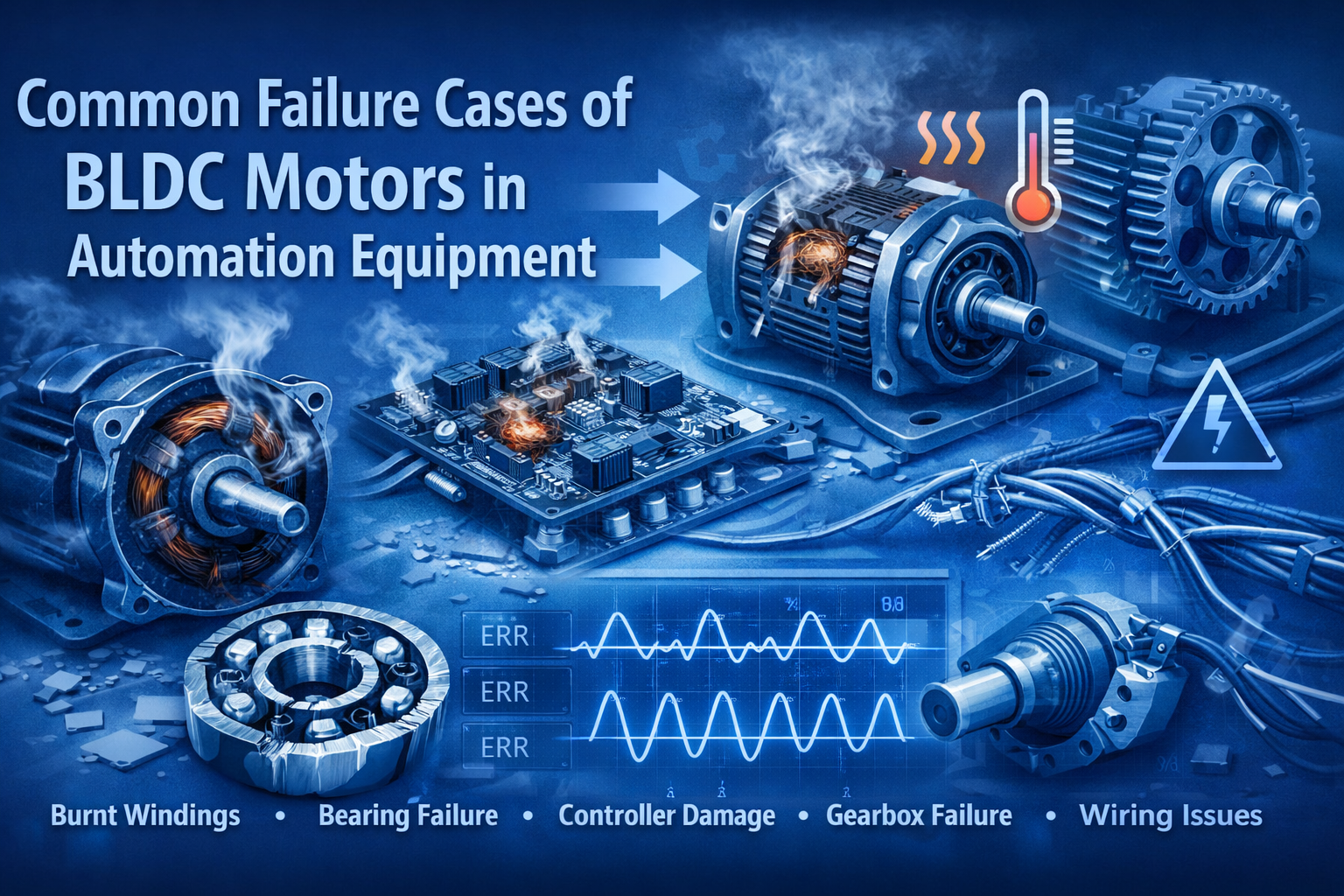

Common Failure Cases of BLDC Motors in Automation Equipment

Brushless DC (BLDC) motors have become the backbone of modern automation equipment. From conveyor systems and robotic arms to AGVs, CNC auxiliaries, and packaging machines, BLDC motors are chosen for their efficiency, long life, compact size, and precise speed control. Yet in real industrial environments, failures still happen — often unexpectedly, sometimes repeatedly, and usually at the worst possible time.

This article brings together common failure cases of BLDC motors in automation equipment, based on real-world observations, buyer concerns, and industry pain points.

Why BLDC Motor Failures Matter More in Automation Systems?

In automation equipment, a motor failure rarely stays isolated. A single BLDC motor problem can stop an entire production line, cause product scrap, or trigger safety shutdowns. Compared with traditional motors, BLDC systems rely heavily on electronic control, sensors, and software logic. This means that failures can be electrical, mechanical, thermal, or even algorithm-related.

For buyers and system designers, the real concern is not whether a BLDC motor can fail, but how predictable the failure is, how easy it is to diagnose, and whether it can be prevented at the design stage. Understanding common failure cases helps reduce total cost of ownership, not just initial motor price.

Failure Case 1: Overheating Due to Continuous Overload

One of the most common BLDC motor failures in automation equipment is overheating caused by continuous overload. In many applications, motors are selected based on nominal torque values, while real operating conditions involve frequent acceleration, deceleration, or unexpected load spikes.

In automated production lines, loads often increase gradually due to mechanical wear, product variation, or process changes. A BLDC motor may continue to run without immediate alarms, but internal temperature slowly rises. Over time, excessive heat degrades winding insulation, weakens permanent magnets, and reduces bearing lubrication quality.

What makes this failure case dangerous is that it often looks like a control issue at first. Engineers may notice speed instability or torque drop before realizing that the motor has been operating beyond its thermal limits for months.

Common symptoms include:

- Motor housing feels abnormally hot

- Reduced torque output under load

- Frequent overcurrent alarms from the drive

- Shortened motor lifespan

Failure Case 2: Insulation Breakdown in High-Humidity Environments

Automation equipment is increasingly used in environments that are far from ideal. Food processing plants, pharmaceutical clean rooms, outdoor logistics systems, and chemical production lines often expose BLDC motors to high humidity or condensation.

Moisture ingress leads to insulation breakdown inside the stator windings. Even when motors are rated with a certain IP protection level, improper cable entry, damaged seals, or poor installation can allow moisture to accumulate over time. Once insulation resistance drops, partial discharge and short circuits become likely.

This type of failure usually develops silently. Motors may pass initial tests but fail after months of operation, especially during seasonal temperature changes.

Key contributing factors:

- Inadequate IP rating for the environment

- Incorrect cable gland selection

- Lack of anti-condensation measures

- Long idle periods followed by sudden startup

Failure Case 3: Bearing Failure Caused by Improper Mounting

Bearing-related failures remain one of the top causes of BLDC motor downtime in automation systems. Unlike traditional motors, BLDC motors are often compact and integrated tightly into mechanical assemblies. Any misalignment, excessive axial load, or mounting stress directly affects bearing life.

A common scenario is flange-mounted BLDC motors installed on frames that are not perfectly flat. The resulting mechanical stress causes uneven bearing load, leading to premature wear, noise, and vibration. In high-speed automation equipment, even small alignment errors can significantly reduce bearing lifespan.

Early warning signs include:

- Abnormal noise during operation

- Increased vibration levels

- Temperature rise near bearing areas

- Reduced positioning accuracy

Failure Case 4: Hall Sensor or Encoder Malfunctions

BLDC motors in automation equipment rely on position feedback devices such as Hall sensors or encoders for commutation and control. Sensor-related failures are more common than many users expect, especially in harsh industrial environments.

Hall sensors may fail due to thermal cycling, vibration, or electromagnetic interference (EMI). Encoders, particularly optical types, are sensitive to dust, oil mist, and mechanical shock. When feedback signals become unstable, the motor may exhibit jerky motion, startup failure, or unexpected stops.

From a buyer’s perspective, this failure case often leads to confusion, as the motor itself may be mechanically sound. Without proper diagnostic tools, the issue can be misattributed to the drive or control software.

Failure Case 5: Drive and Motor Mismatch

Another frequent issue seen in automation projects is improper matching between the BLDC motor and its drive. Even when voltage and current ratings appear compatible, differences in control algorithms, commutation methods, and protection logic can cause long-term reliability problems.

Some drives apply aggressive current control strategies that increase torque ripple or thermal stress. Others may not provide adequate protection against stall conditions. Over time, this mismatch accelerates motor aging and increases failure risk.

At United Motion Inc., we often see cases where motors perform well during initial commissioning but fail after extended operation due to subtle incompatibilities between motor characteristics and drive settings.

Failure Case 6: EMI and Grounding Issues in Automation Panels

As automation systems become more compact and complex, electromagnetic interference has become a serious concern. BLDC motors generate high-frequency switching noise, which can interfere with sensors, PLCs, and communication networks if grounding and shielding are not properly designed.

Poor grounding may also create circulating currents that pass through motor bearings, causing electrical pitting and premature failure. These issues are often overlooked during system design but can have long-term consequences.

Typical symptoms include:

- Random communication errors

- Unexplained encoder faults

- Premature bearing damage

- Drive resets or alarms

Failure Case 7: Thermal Cycling and Magnet Demagnetization

In automation equipment with frequent start-stop cycles, BLDC motors experience repeated thermal cycling. Over time, this can weaken permanent magnets, especially if the motor operates close to its maximum temperature rating.

Partial demagnetization reduces torque capability and efficiency. The motor may still run, but performance gradually declines, leading to compensation attempts through higher current, which further accelerates degradation.

This failure mode is difficult to detect without detailed performance testing, making it a hidden risk in long-term automation projects.

Failure Case 8: Poor Cable Management and Connector Failures

Cabling is often treated as a secondary concern, yet many BLDC motor failures in automation equipment are linked to cable fatigue, loose connectors, or improper strain relief. Continuous motion, vibration, and bending stress can damage power and signal cables over time.

Intermittent connections may cause sudden stops, false alarms, or even damage to the drive electronics. In high-speed automation lines, these issues can be extremely costly.

Failure Case 9: Software and Parameter Misconfiguration

Modern BLDC motor systems are deeply integrated with software. Incorrect parameter settings, such as current limits, acceleration ramps, or thermal protection thresholds, can create conditions that lead to premature motor failure.

In some cases, performance optimization during commissioning focuses on short-term speed or accuracy, while ignoring long-term thermal and mechanical stress. Over time, this imbalance results in failures that appear mysterious but are rooted in configuration choices.

Failure Case 10: Inadequate Preventive Maintenance

Despite being labeled as “low maintenance,” BLDC motors in automation equipment still require regular inspection. Dust buildup, cooling path blockage, and lubricant degradation can all reduce motor life if left unaddressed.

Many failures occur not because the motor design is flawed, but because early warning signs were missed. A simple vibration check or thermal inspection could prevent major downtime.

What Buyers and Engineers Can Learn from These Failure Cases?

The common thread across these BLDC motor failure cases is not technology limitation, but system-level decision-making. Proper motor selection, realistic load analysis, environmental consideration, and correct integration practices significantly reduce failure risk.

From a buyer’s search perspective, keywords such as BLDC motor failure analysis, industrial BLDC motor reliability, automation motor troubleshooting, and brushless DC motor maintenance reflect a growing demand for practical guidance rather than marketing promises.

At United Motion Inc., we believe that sharing real-world insights builds trust and helps customers design more reliable automation systems.

Best Practices to Reduce BLDC Motor Failures in Automation Equipment

- Select motors with sufficient thermal margin

- Match motors and drives from compatible suppliers

- Design for environmental protection from the start

- Ensure proper grounding and EMI control

- Implement condition monitoring where possible

- Train maintenance teams to recognize early symptoms

These steps may slightly increase upfront cost, but they significantly reduce lifecycle expenses and unplanned downtime.

References

1. IEC 60034 – Rotating Electrical Machines Standards

2. IEEE Industry Applications Society – Motor Reliability Studies

3. NEMA MG-1 Motor and Generator Standards

4. “Brushless DC Motor Fundamentals” – Texas Instruments Application Notes

5. SKF Bearing Failure Analysis Handbook

Related blog: What Is a BLDC Motor in a Washing Machine?