How to Reduce Noise and Vibration in BLDC Motors?

Noise and vibration are two of the most common challenges engineers, product designers, and equipment manufacturers face when working with BLDC motors. While brushless DC motors are known for high efficiency, long lifespan, and precise control, poor noise and vibration performance can quickly undermine product quality, user experience, and even system reliability. In industries such as automation, medical devices, electric vehicles, HVAC, and robotics, excessive motor noise is no longer acceptable. Buyers are actively searching for quieter, smoother, and more reliable motor solutions.

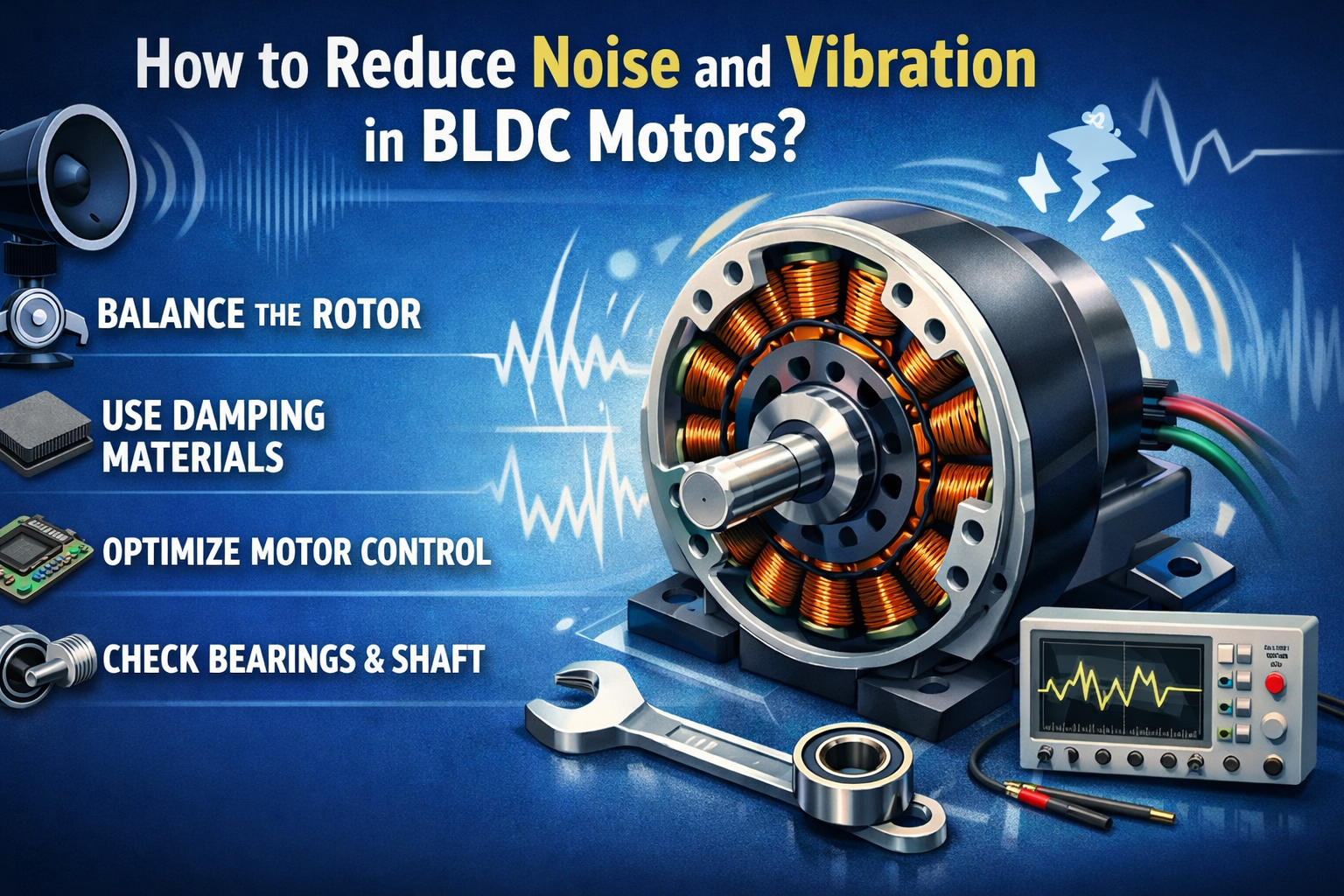

Reducing noise and vibration in BLDC motors is not about a single fix. It requires a clear understanding of electromagnetic design, mechanical structure, motor control algorithms, manufacturing accuracy, and system-level integration. This guide brings together practical engineering insight, industry best practices, and real-world considerations to help you understand where noise and vibration come from and how to effectively minimize them.

Understanding Noise and Vibration in BLDC Motors

Before discussing solutions, it is important to understand what noise and vibration actually mean in the context of BLDC motors. Noise is the audible sound produced during motor operation, while vibration refers to mechanical oscillations that may or may not be audible but can still damage equipment over time.

In BLDC motors, noise and vibration are closely linked. Mechanical vibration often becomes airborne noise, and electromagnetic forces inside the motor can excite mechanical resonances. Buyers searching for “low noise BLDC motor” or “quiet brushless DC motor” are often dealing with systems where even small disturbances become noticeable.

Noise and vibration in BLDC motors typically fall into three main categories: electromagnetic, mechanical, and aerodynamic. Each category has different causes and requires different mitigation strategies.

Electromagnetic Sources of Noise and Vibration

Electromagnetic noise is one of the most common causes of vibration in BLDC motors, especially at low and medium speeds. It originates from the interaction between the stator magnetic field and the rotor magnets. Any imbalance or fluctuation in this interaction produces radial and tangential forces that can excite vibration.

Cogging Torque and Torque Ripple

Cogging torque is a major contributor to noise in BLDC motors. It occurs due to the interaction between permanent magnets and stator slots, even when no current is applied. Torque ripple, on the other hand, occurs during operation when current commutation causes uneven torque output.

High cogging torque leads to speed fluctuation, vibration, and audible noise, especially in precision applications such as medical equipment, gimbals, and laboratory instruments. Reducing cogging torque is one of the first priorities in low-noise BLDC motor design.

Common solutions include:

- Optimizing slot and pole combinations

- Using skewed stator slots or rotor magnets

- Applying fractional-slot winding designs

- Improving magnet shaping and magnetization patterns

Magnetic Imbalance and Flux Harmonics

Magnetic imbalance occurs when the magnetic field is not evenly distributed around the air gap. This can be caused by magnet tolerances, uneven air gap, or manufacturing variations. Flux harmonics generated by PWM switching and non-ideal winding layouts also contribute to vibration.

These harmonics create pulsating forces that excite the motor housing and connected structures. In applications like industrial automation or electric vehicles, these vibrations can propagate through frames and panels, amplifying noise.

Reducing magnetic harmonics involves:

- High-precision magnet placement

- Optimized winding distribution

- Advanced motor control algorithms

- Improved stator lamination quality

Mechanical Sources of Noise and Vibration

Mechanical noise is often easier to identify but not always easier to fix. It usually results from physical contact, imbalance, or structural resonance.

Rotor Imbalance

Even a small rotor imbalance can cause significant vibration at high speeds. This is especially critical in high-speed BLDC motors used in blowers, pumps, and spindles. Imbalance leads to centrifugal forces that increase exponentially with speed. Dynamic balancing during manufacturing is essential. High-quality BLDC motors typically undergo multi-plane balancing to ensure smooth operation across the entire speed range.

Bearing Noise and Wear

Bearings are one of the most overlooked sources of noise in BLDC motors. Low-quality bearings, improper preload, contamination, or incorrect lubrication can all generate noise and vibration.

For low-noise applications, bearing selection is critical. Options include:

- Precision ball bearings with low noise ratings

- Ceramic hybrid bearings for high-speed applications

- Sleeve bearings for ultra-quiet, low-load designs

Proper bearing installation and alignment are just as important as bearing selection. Even premium bearings will generate noise if installed incorrectly.

Shaft Misalignment and Mechanical Assembly

Misalignment between the motor shaft and the load introduces axial and radial forces that increase vibration. Over time, this not only creates noise but also reduces bearing life and motor reliability.

Precision machining, tight assembly tolerances, and flexible couplings are common solutions. In system-level design, ensuring that the motor is not forced into misalignment by the mounting structure is equally important.

Aerodynamic Noise in BLDC Motors

Aerodynamic noise is often underestimated, especially in fan and blower applications. As the rotor spins, air turbulence around the rotor, fan blades, and housing generates noise.

This type of noise becomes dominant at higher speeds and is strongly influenced by motor geometry and enclosure design.

Ways to reduce aerodynamic noise include:

- Optimized fan blade design

- Smooth airflow paths

- Reduced sharp edges and gaps

- Proper ventilation hole placement

In many cases, aerodynamic noise can be reduced without changing the motor itself, simply by redesigning the surrounding airflow system.

The Role of Motor Control in Noise Reduction

Motor control plays a major role in how quiet a BLDC motor operates. Even a well-designed motor can become noisy if driven poorly.

PWM Switching Frequency

Pulse Width Modulation (PWM) is essential for speed and torque control, but it also introduces switching noise. Low PWM frequencies can cause audible whining, while high frequencies increase switching losses.

Selecting an appropriate PWM frequency that balances efficiency and noise is critical. Many modern BLDC motor drivers support adjustable PWM frequencies specifically to address noise concerns.

Commutation Methods

Trapezoidal commutation is simple and cost-effective, but it tends to produce more torque ripple and noise. Sinusoidal commutation and field-oriented control (FOC) provide smoother torque and significantly lower noise. For applications where quiet operation is a priority, FOC is often the preferred choice. It reduces current harmonics and electromagnetic vibration, especially at low speeds.

Current Loop Tuning

Poorly tuned current control loops can cause oscillations that translate directly into vibration and noise. Proper tuning of current, speed, and position loops is essential for stable and quiet motor operation. This is particularly important in servo-driven BLDC motors, where precision and smooth motion are critical.

Structural Design and Damping Techniques

Even when electromagnetic and mechanical sources are minimized, vibration can still be amplified by structural resonance.

Motor Housing Design

The motor housing acts as a sound radiator. Thin or poorly supported housings can amplify vibration and convert it into audible noise.

Using thicker walls, ribbed structures, or damping materials can significantly reduce noise radiation. Aluminum housings with optimized geometry are commonly used for this reason.

Isolation and Mounting

How the motor is mounted to the system has a major impact on noise transmission. Rigid mounting can transfer vibration directly into the machine frame, while vibration-isolating mounts can significantly reduce noise.

Rubber mounts, elastomer isolators, and compliant couplings are commonly used in noise-sensitive applications.

Manufacturing Quality and Consistency

Noise and vibration are often symptoms of inconsistent manufacturing quality. Variations in winding tension, magnet placement, air gap uniformity, and bearing installation all contribute to unpredictable noise behavior.

Working with an experienced BLDC motor manufacturer is essential. At United Motion Inc., strict quality control processes and end-of-line testing help ensure consistent noise and vibration performance across production batches.

Application-Specific Noise Reduction Strategies

Different applications have different noise tolerance levels. What is acceptable in industrial machinery may be unacceptable in medical or consumer devices.

Medical and Laboratory Equipment

In medical applications, even low-level noise can be problematic. Solutions often include:

- Ultra-low cogging motor designs

- Sinusoidal control with FOC

- Precision bearings

- Acoustic enclosures

Electric Vehicles and Mobility

In EVs and e-bikes, motor noise affects user perception and brand quality. Smooth torque delivery, optimized PWM strategies, and robust mechanical design are critical.

Industrial Automation

In factories, vibration affects positioning accuracy and long-term reliability. Reducing vibration improves not only noise but also system precision and lifespan.

Testing and Measurement of Noise and Vibration

Effective noise reduction requires proper measurement. Common techniques include:

- Sound pressure level (SPL) testing

- Vibration acceleration measurement

- Frequency spectrum analysis

- Order tracking analysis

Testing helps identify dominant noise sources and evaluate the effectiveness of design improvements.

Why Buyers Care About Low-Noise BLDC Motors

From a buyer’s perspective, low noise and vibration translate into:

- Higher perceived product quality

- Better user experience

- Reduced maintenance

- Longer equipment life

- Compliance with regulatory standards

Search trends clearly show growing demand for “quiet BLDC motors” and “low vibration brushless motors,” especially in high-value applications.

How United Motion Inc. Supports Low-Noise BLDC Motor Solutions?

At United Motion Inc., we combine electromagnetic optimization, precision manufacturing, and advanced motor control expertise to deliver BLDC motors designed for low noise and vibration. Our engineering team works closely with customers to understand application requirements and provide customized motor solutions that meet performance, reliability, and acoustic expectations.

References

IEEE Transactions on Industry Applications – Electromagnetic Noise in Electric Motors

Bosch Rexroth – Motor Control and Noise Reduction Techniques

NEMA MG-1 Standards for Motors and Generators

ISO 10816 – Mechanical Vibration Evaluation

Texas Instruments – BLDC Motor Control and Acoustic Noise

Siemens Technical Papers – Reducing Motor Noise and Vibration

Related blog: Top Mistakes to Avoid When Selecting a BLDC Motor