WSD-H3 Series High Performance Servo

The WSD-H3 Series High Performance Servo Drive offers reliable and precise motion control for industrial automation applications. With a wide power range from 50 W to 7.5 kW, it supports single-phase and three-phase AC power inputs (220 V / 380 V) to fit various system requirements.

Designed for stable operation and fast response, the WSD-H3 series delivers strong peak current capability for smooth acceleration and accurate control. Selected models feature a built-in brake resistor, improving braking performance and operational safety. Its compact design makes it suitable for CNC machines, robotics, packaging, and other automation equipment.

Product List

| Type | WSD-H3 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0005 | 0010 | 0020 | 0040 | 0075 | 0100 | 0150 | 0085 | 0130 | 0180 | 0290 | 0440 | 0550 | 0750 | |

| Rated power (W) | 50 | 100 | 200 | 400 | 750 | 1k | 1.5k | 850 | 1.3k | 1.8k | 2.9k | 4.4k | 5.5k | 7.5k |

| Rated current (A) | 1.2 | 1.2 | 1.5 | 2.3 | 4.1 | 6.1 | 9.5 | 3.6 | 5.7 | 7.1 | 12.3 | 18.5 | 19.1 | 24.4 |

| Peak current (A) | 4.2 | 4.2 | 5.4 | 8.4 | 14.5 | 21.5 | 33.3 | 10.8 | 16.9 | 21.4 | 36.9 | 55.5 | 57.3 | 73.2 |

| Power circuit | Single phase AC 220V | Single phase AC 220V | Single phase AC 380V |

|||||||||||

| Controlpower supply | Single/three phase AC 220V | Three phase AC 380V |

||||||||||||

| Brake resistor | No built-in | Built-in | ||||||||||||

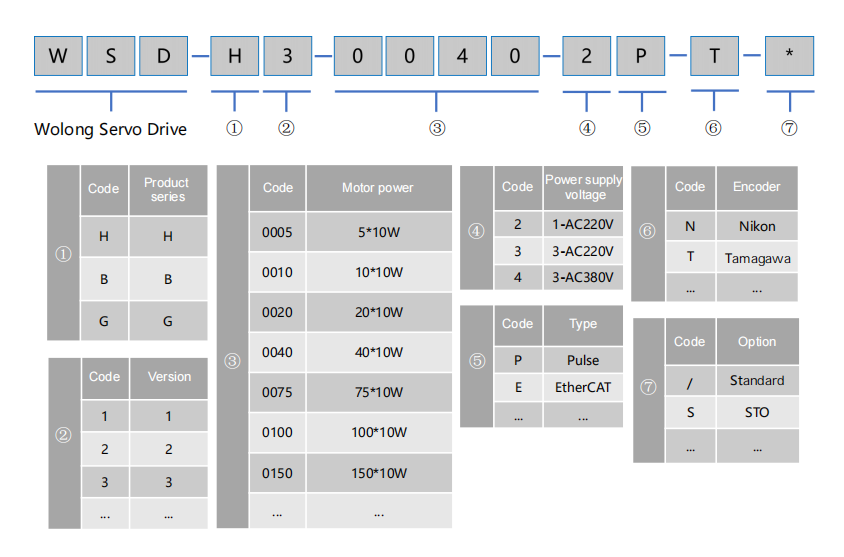

Naming Rules of H3 Series

General Technical Specifications

| Item | Contents | |

|---|---|---|

| Input power | Single/Three phase AC 220V/380V,50/60Hz,-15%~+10% | |

| Control mode | IGBT PWM control,Sine wave drive mode | |

| Surroundig conditions | Temperature | Operating temperature: 0-50ÿ℃(No condensation) Storage temperature: -20 to 65℃ |

| Humidity | Less than 20~85%RH (No condensation) | |

| Altitude | Less than 1000m | |

| Vibration | Below 5 m/s ², 10 to 60 Hz(cannot be used continuously when there is a resonance point) |

|

| Encoder feedback | 17/20/23bit communication encoder | |

| Communication | USB | After being connected to a computer, parameters can be set for monitoring and other purposes |

| Front panel | Five eight-section LED digital tubes and four buttons | |

| Regenerative resistor | For 400W and below, external connection is required; for 750W and above, internal connection is needed | |

| Dynamic brake | Have | |

| Vibration suppression | Up to 4 notch frequencies and 4 end vibration suppression frequencies can be used | |

| Automatic gain adjustment | The load inertia can be automatically adjusted by the action instructions inside the driver, and the corresponding gain parameters can be automatically set | |

| Alarm | It includes overvoltage, undervoltage, overspeed, overload, overheating, overcurrent, encoder abnormality, etc | |

| Cooling | A:Natural cooling B-E:Air cooling |

|

Application in Different Scenarios

Customer Service

United Motion Inc.’s motion solution apply in diverse areas all around the world.

Our sales and engineering support teams are ready to assist you with any questions, including quotation, application support, and product configuration.

Please submit your requirements through our Custom Service Form to ensure a faster response. Or you can reach us at info@unitedmotioninc.com for general inquiries.

Tell Us About Your Application Requirements

United Motion Inc welcomes inquiries and challenges. If you find our standard products cannot meet your need, please feel free to contact us for customization. Our professional engineering and service team will quickly review your need and propose a solution if we can make it.

We look forward to communicating and collaborating with you!