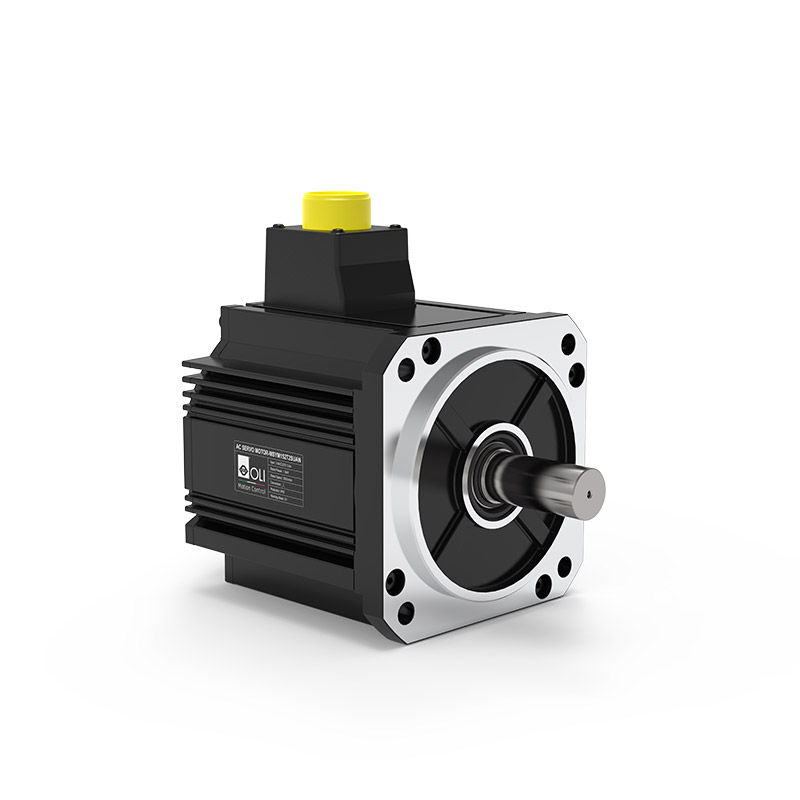

The MSYM medium-capacity servo series delivers 1.0 to 3.0 kW of output power with rated torque from 4.78 to 14.3 N·m, making it a highly versatile solution for general industrial automation. Its balanced medium-inertia design—ranging from 4.6 to 12.9 ×10⁻⁴ kg·m²—provides excellent load adaptability, smooth motion, and easier tuning across a wide variety of mechanical systems. Operating at 2000 r/min with a maximum speed of 3000 r/min, the MSYM series is ideal for conveyors, assembly lines, packaging equipment, and material-handling applications that require stable performance, reliable torque delivery, and broad compatibility with different load conditions.

Technical Specification

| Motor model | MSYM102T2* | MSYM152T2* | MSYM202T2* | MSYM302T2* |

| Flange | 130 | |||

| Voltage(V) | AC 220 | |||

| Rated output(kW) | 1 | 1.5 | 2 | 3 |

| Rated torque(N·m) | 4.78 | 7.17 | 9.55 | 14.3 |

| Max torque(N·m) | 14.3 | 21.5 | 28.6 | 42.9 |

| Rated current(A) | 5.9 | 9.7 | 11.4 | 17.4 |

| Max current(A) | 24 | 40 | 49 | 74 |

| Rated speed(r/min) | 2000 | 2000 | 2000 | 2000 |

| Max speed(r/min) | 3000 | 3000 | 3000 | 3000 |

| Moment of inertia(x10-4kg·㎡) | 4.6(6.4) | 6.7(8.5) | 8.7(10.5) | 12.9(14.7) |

| Servo driver compatibility | WSDH201002*/WSDB301002* | WSDH201503*/WSDB301503* | WSDH202003*/WSDB302003* | WSDH203003*/WSDB303003* |

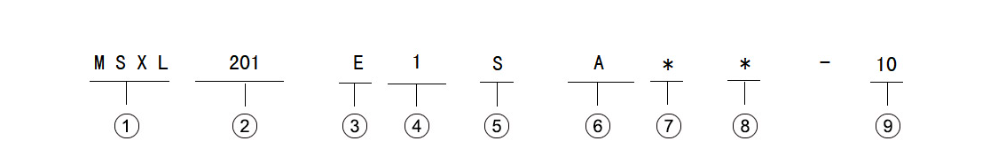

| ① | ③ | ⑥ Sturcture | ||||||||||

| Code | Inertia | Code | Pole | Code | Shaft | Brake | Oil seal | |||||

| MSXL | Low Inertia | E | 8P | Shaft | Key | N | Y | N | Y | |||

| MCXL | Low Inertia | T | 10P | A | ● | ● | ● | |||||

| MSYM | Medium Inertia | ④ | B | ● | ● | ● | ||||||

| MSTM | Medium Inertia | Code | V | C | ● | ● | ● | |||||

| MIXH | High Inertia | 0 | 24V | D | ● | ● | ● | |||||

| MIYH | High Inertia | 1 | 100V | S | ● | ● | ● | |||||

| ② | 2 | 200V | T | ● | ● | ● | ||||||

| Code | Rated Power | 4 | 400V | U | ● | ● | ● | |||||

| 500 | 50*1W | A | 48V | V | ● | ● | ● | |||||

| 201 | 20*10W | B | 72V | Note: 7&8 digits are internal identification codes | ||||||||

| 401 | 40*10W | ⑤ | ||||||||||

| 751 | 75*10W | Code | Encoder | ⑨ | ||||||||

| 102 | 10*100W | F | Incremental 2500P 14 wire | Code | Reduction ratio | |||||||

| 152 | 15*100W | E | Incremental 2500P 8 wire | 10 | 10:01 | |||||||

| 202 | 20*100W | S | Single Turn Absolute Value 20bit | 15 | 15:01 | |||||||

| 302 | 30*100W | I | Single Turn Absolute Value 17bit | ②: MS/MC for SPM design MI for IPM design | ||||||||

| 502 | 50*100W | Z | Single Turn Absolute Value 23/24bit | |||||||||

| 752 | 75*100W | M | Multiple Turns Absolute Value 20+16bit | |||||||||

| 113 | 11*1000W | A | Multiple Turns Absolute Value 17+16bit | |||||||||

| … | … | D | Multiple Turns Absolute Value 23/24+16bit | |||||||||

Application in Different Scenarios

Customer Service

United Motion Inc.’s motion solution apply in diverse areas all around the world.

Our sales and engineering support teams are ready to assist you with any questions, including quotation, application support, and product configuration.

Please submit your requirements through our Custom Service Form to ensure a faster response. Or you can reach us at info@unitedmotioninc.com for general inquiries.

Tell Us About Your Application Requirements

United Motion Inc welcomes inquiries and challenges. If you find our standard products cannot meet your need, please feel free to contact us for customization. Our professional engineering and service team will quickly review your need and propose a solution if we can make it.

We look forward to communicating and collaborating with you!